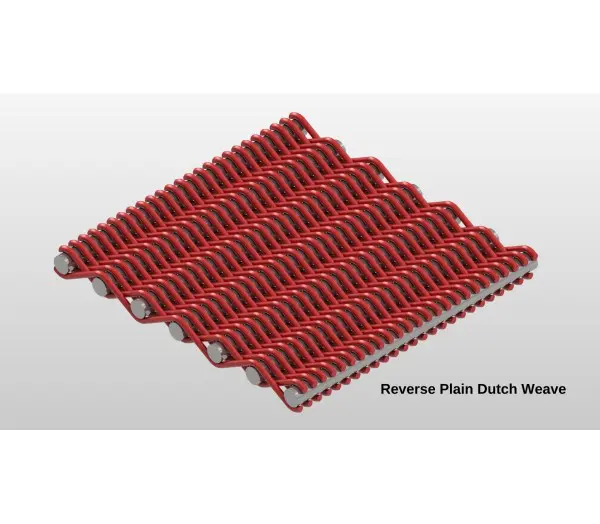

Micronic Mesh in Stock from Gerard Daniel

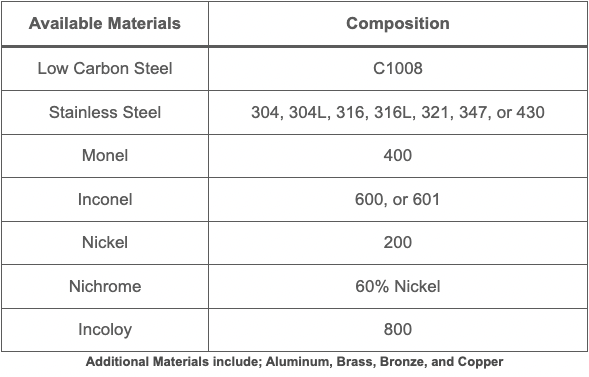

Micronic mesh (or micron mesh) is typically used for liquid filtration applications due to the extremely small openings (measured in microns) in the weave. Micron mesh can have greater strength and durability compared to square weave wire mesh. Micron retention size (what the mesh is intended to trap) is the primary parameter needed to determine the correct weave and size. Dutch and Twilled Dutch are the two main types of weaves, with the most common alloys listed in the table.

Supply Chain Problems

Aren’t Your Production Line’s Problem

Wire mesh is a small part of a larger whole, but when that small part is off, the whole production line will notice. When you need micronic wire mesh at the right spec, at the right time, and at the right cost, then you need the engineers at Gerard Daniel. Where other suppliers can’t keep up, we can.

- Most micronic mesh sizes in stock are 48” wide by hundreds of feet long

- Other sizes are available on request.

- We can slit rolls down to 1/4” usually within a few days

- We carry DFARS stock in standard stainless steel alloys.

- We can laser-cut in small quantities to any shape within a week depending on material availability.

- We can stamp high volume custom shapes for micron mesh filter elements pending tooling lead time.

- We can weave custom micron wire mesh screen to your specifications.

The Wire Mesh You Need...

Whether we source your mesh or weave it ourselves, rest assured you’ll get the highest repeatable performance in micron mesh from our warehouse – supported by filtration expertise and supply chain mastery.

Plain Dutch Weave Wire Mesh

The wire in a dutch weave is interwoven but the warp wires are thicker than the shute wires. These are arranged very close together to form a zero-mesh structure. This generates a weave that has high inherent stability with a relatively small mesh size. Dutch weave has excellent filtration qualities and can be easily cleaned of filtrate deposits and residual dirt.

- Micron retention: 35 – 310

- Porosity: 43% – 66%

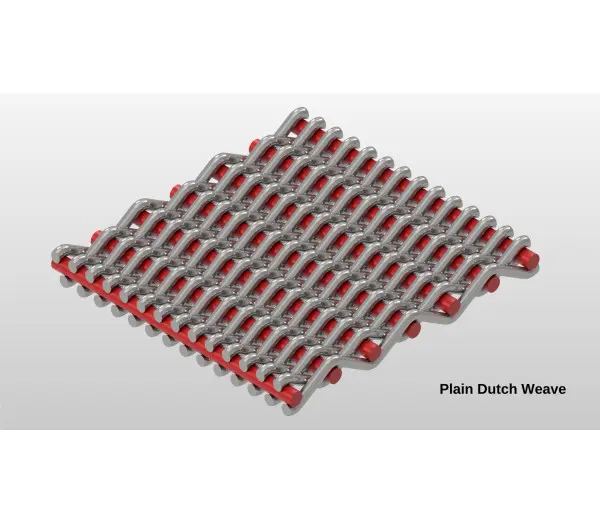

Reverse Plain Dutch Weave

“Reverse” describes the fact that the warp wires of this weave are relatively thin and the shute wires are thick – in other words, the exact opposite of the standard dutch weaves. The reverse dutch design, sometimes referred to as “Microdur,” produces precisely defined pore openings that run under an angle to the surface of the mesh. The high number of warp wires increases the active filtration cross section of the mesh.

- Micron retention: 10 – 200

- Porosity: 45% – 66%

Twilled Dutch Weave Wire Mesh

As with Dutch weave, the shute wires are arranged as close together as possible. However, this weave has double the number of shute wires than a plain dutch weave. A very small aperture is formed by three shute wires which cross in different directions and, together with the warp wires, create a channel that is open on two sides. The structure of this tight weave provides high filtration accuracy. Another variation is Open Twill Dutch Weave Wire Mesh where fewer shute wires are used to influence the filtration rate.

- Micron retention: 1 – 200

- Porosity: 29% – 59%

Reverse Dutch Twilled Mesh

An important version of the reverse dutch weave is the reverse dutch twilled weave. With this weave, the warp wires are also relatively thin – as in the case of the normal reverse dutch weave. The difference is the twilled weave pattern of the shute wires. This means that the warp wires are not as heavily deformed and physically stressed as in the case of plain weaves. The strength of this weave design is its suitability for applications that are subject to high levels of mechanical stress.

- Micron retention: 55 – 400

- Porosity: 39% – 61%

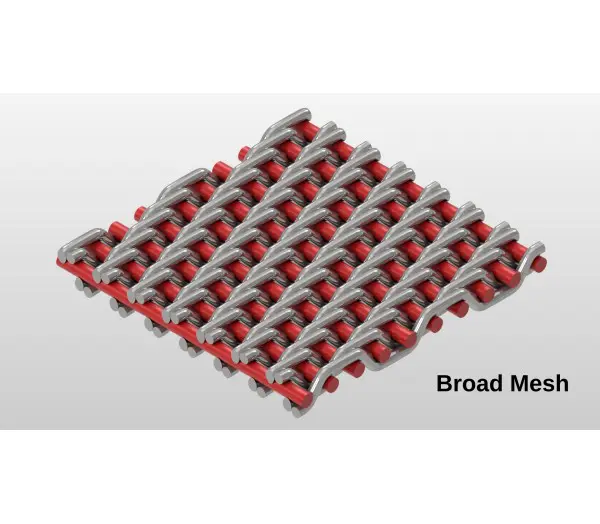

Broad Weave Mesh

To optimize the filtration capacity of the broad weave mesh cloth, the shute wires of the broad mesh twilled weave are arranged loosely instead of being close to each other. This means that the retention accuracy is lower than that of a classic twilled weave. Nevertheless, the accuracy is sufficient for the requirements of most applications. The surface of the BMT cloth is smooth on both sides, meaning that the filter can be easily cleaned.

- Micron retention: 13 – 45

- Porosity: 40% – 65%

…Exactly When & Where You Need It

Extensive Ready-to-Ship

Wire Mesh Inventory

Gerard Daniel is known for having the largest wire cloth inventory in North America. We stock and have immediate availability of more than 5,000 different types of wire mesh and cloth and can easily source many others. For stocked items, we offer same-day or next-day shipping. Choose to ship products air, ground, and sea freight to suit your timescale.

Inventory Management

Our goal is to keep your product line running using the least amount of administrative effort, whether that’s through blanket order agreements, our proprietary CRS program, or a custom solution.

Continuous Replenishment Service

Our proprietary Continuous Replenishment Service (CRS) is available for select customers. Always have inventory on hand, without having to invest financially until it's consumed.

When Your 200 Micron Mesh Purchasing

Is Down To The Wire

Is your production line in danger of grinding to a halt? Without the right wire mesh supplier, the answer is yes. Keep your production line moving with 200 micron wire mesh from Gerard Daniel.